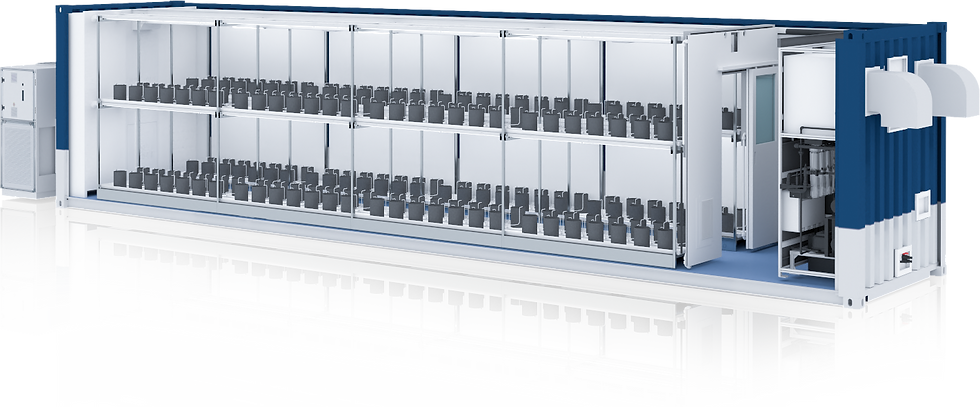

BioCube Container

Portable, All-in-One

Indoor Farming Solution for

Cultivation, Propagation & Research

CROP PRODUCTION

Growing Container

Microgreens

Up to 230 Planting Trays (per cntr.)

Up to 13.46 Tonnes Annum Yield (per cntr.)

80 M² Canopy Area

40 Sections | 5 Tiers | 2 Rows

Dried Flowers

Up to 252 Planting Bags (per cntr.)

Up to 120 kg Annum Yield (per cntr.)

30.4 M² Canopy Area

16 Sections | 2 Tiers

Aeroponics

Cultivation

Customised Lighting

Strategy

Fully Integrated

HVAC

SaaS & IoT

Support

Space & Energy

Efficiency

Scalable &

Expandable

OPERATIONAL SUPPORT

Supporting Container

CF-SPC01:

Designed for Efficient Crop Propagation Support

This container is ideal for small-scale propagation needs or where additional space is required for packaging or cleaning.

-

Entrance Area: Includes an air shower, wardrobe, and shoe storage to ensure contamination-free entry.

-

Small Propagation Area: Equipped for plant mothering and cloning with self-supporting Fertigation and Irrigation Control (FIC).

-

Corridor Area: Features an advanced air purification system to maintain an optimal environment.

-

Working Areas: Designed for trimming and drying processes.

CF-SPC02:

Optimised for Large-Scale Propagation

A practical solution for expanded propagation needs or operations requiring additional packaging and cleaning capacity.

-

Entrance Area: Equipped with an air shower, wardrobe, and shoe storage for controlled access.

-

Large Propagation Area: Supports plant mothering and cloning, complete with self-supporting FIC.

-

Corridor Area: Integrated air purification system for maintaining sterile conditions.

-

Working Areas: Dedicated to trimming activities.

CF-SPC03:

Perfect for Post-Harvest Operations

Tailored for larger-scale crop management tasks, including drying and storage.

-

Entrance Area: Features a purification section with an air shower, wardrobe, and shoe storage to uphold hygiene standards.

-

Working Areas: Includes expanded drying zones and ample storage space for post-harvest operations.

TECHNICAL PARAMETRES

GENERAL

-

Power Connector: 5-Core 125A + 5-Core 63A

-

General Water Supply Pipe: DN20

-

General Water Drain Pipe: DN20

-

Overflow Drain Piple: DN15

-

Input Voltage: 380V 3 Phase 50/60Hz

-

Rated Power: 20KW

-

Peak Current: 80A @ 380V

-

Ambient Temp.Range: -18°C to 42°C

-

Ambient R.H: 20% - 95%

LIGHTING SYSTEM

-

Power/Light: 24W

-

QTY of Light: 3,750 pcs

-

Total Power: 9,000W

-

Diming: 10% - 100%

-

Total PPF: 25,200 μmol/s

-

PPFD: 300μmol·m ²·s ¹ @28cm

-

PPE : 2.8μmol / J

-

Spectrum: Full Spectrum

MICRO CLIMATE PROCESSING

-

Cooling Capacity: 26kW (Peak)

-

Cooling Mode: Variable Frequency Air-Cooled DX.

-

Ventilation: 4,000CMH

-

Air-Exchange Rate: 15%

-

External Pressure: 300CMH

-

Dehumidification: 13L/Hr @30°C 80%

-

Light Period Climate Range: >60% @ 20°C

-

Dark Period Climate Range: >70% @18°C

-

Photohydrogen Density: 10¹¹/m³

INTELLEGENT FERTILIZING

-

Fertilizer Channel: 3 + 1

-

Fertilizer Tank: 4 pcs * 10L

-

PH Monitor Range: 0.00 -14.00

-

PH Calibrate Frequency: 7 days

-

EC Monitor Range: 0.00 - 20ms/cm

-

EC Calibrate Frequency: 7 days

-

Peristaltic Pump Flow: 100ml/minutes

AEROPONICS IRRIGATION

-

UV Sterilizer Power: 100W

-

Irrigation Pressure: 3 - 4.5bar (43 - 72psi)

-

Droplets Diameters: -

-

20μm - 60μm: 75%

-

<20μm: 5%

-

>60μm: 20%

-

Main Reservoir Volume: 650L

-

Circulate Reservoir Volume: 150L

-

Solution Temperature: be settled between 15°C to 28°C

CONTROL SYSTEM

-

Computer Processor: APU (Agricultrue Processing Unit )

ARM Cortex-M4 32 -

IO Port: 114 >5V

-

Storage: 1024K Flash,192K SRAM +128M

-

Screen Size: 374.45mm *229.9mm*11.5mm

-

Screen Driving Scheme: a-Si TFT Active Matrix

-

Number of Pixels: 1920*1080 pixel

-

Surface Treatment: Anti-glare,Haze 25%,Hard Coating(3H)

-

Ethernet Port: 100/1000M BASE

-

WIFI/BT: WIFI 6/BT 5.0(optional)

Application Scenes

FAQs

The BioCube Container is engineered to GMP and GAP standards, offering fully transportable and adaptable chambers suitable for growing, propagation, trimming, drying, and storage. It provides setup options for diverse crops, enhancing scalability and versatility.

Equipped with Total Controlled Environment Agriculture (T-CEA) technology, the BioCube Container ensures precise control over temperature, humidity, CO₂ levels, lighting, and airflow, making it suitable for year-round cultivation in any climate.

Yes, the BioCube Container is equipped with advanced environmental controls that enable efficient cultivation in any climate. This ensures consistent quality and yield, regardless of external weather conditions. Notably, during cooler weather, the Smart Mode activates, drawing in external air to reduce energy consumption by approximately 50%.

Absolutely. Its space-efficient design, reduced resource use (water, energy, and nutrients), and high-yield capabilities make it an ideal solution for scaling operations while maintaining profitability.

Yes, the BioCube is highly suitable for commercial strawberry production, as well as for leafy greens, microgreens, tall plants, herbs, and medicinal plants. Designed with scalability in mind, it helps commercial growers optimise space utilisation while delivering significant cost savings through reduced water, nutrient, and energy consumption.

The GS-DRIP system ensures 90% nutrient and water delivery efficiency directly to the roots, significantly reducing water waste and the risk of disease. Its precise emitters and recirculating mechanism optimise resource use, enhancing crop yield and quality while also being easy to set up and maintain, adaptable to various growth stages.